Balji Yu.A.

The primary importance in assessing the safety of meat is its microbiological indicators. An important role in the development of microorganisms is played by the degree of exsanguination of carcasses (Ali, A.M., Lawson, M.A. et al., 2007; Alvarado, C., Richards, M. et al., 2007; Maqsood, S., Benjakul, S., 2011). Poorly exsanguinated meat, if the hygienic conditions of storage and sale are not observed, is more quickly subjected to spoilage. Exsanguination is a very important technological process, since the degree of blood removal depends on the presentation of the carcasses and the probability of subsequent microbiological damage to the meat. The degree of exsanguination of carcasses depends on the technology of slaughter, the physiological state of the animal before slaughter, and other factors (Ali, A.M., Abdalla, H.O., Mahgoub, I.M., 2011; Nakyinsige, K., Fatimah, A. et al., 2014). But in any case, the output of blood slows down with pre-slaughter stress and fatigue of animals, because these conditions increase the flow of blood to the muscles. Also, poor blood output is observed in the sickly state of the animal and, accordingly, if the meat is obtained from a fallen animal, the blood remains completely in the carcass. With complete exsanguination, 50-60% of all blood is removed. With incomplete exsanguination, the yield of meat is higher, but it has a dark color and spoils faster.

The use of pre-stunning during the slaughter of animals should ensure that the animal remains alive until the process of exsanguination. This is determined by the presence of motor functions, a beating heart, and the ability to exsanguinate well (Fuseini A, Knowles TG. et al., 2016). However, motor abilities alone cannot be evaluated, since they can continue even after the death of the animal (Jain, S., DeGeorgia, S., 2005). It is also impossible to evaluate the heartbeat alone, since, for example, after stunning an animal with a firing device or a hammer blow, instant death can occur as a result of the destruction of the skull and brain. At the same time, the work of the heart can still continue for 8-10 minutes (Grandin T., 2015). The Halal Food Standards Alliance of America (HFSAA, 2016) interprets the ability of good exsanguination after stunning as meat obtained from a live animal, i.e. not killed during the stunning process.

In the event that the animal dies before the process of exsanguination from stunning, the meat will already be considered cadaverous and not suitable for human consumption. But it happens that such a carcass is still sold, which happens in commercial meat processing enterprises. So, at the end of 2016, a scandal broke out in the capital of Kyrgyzstan, Bishkek. Mass cases of sale of meat of the fallen animals on unauthorized places of trade and production of sausage products from it were found (Kosybekov A., 2016).

In this regard, the actual task of the regulatory authorities is to provide high-quality and safe livestock products at the stage of their sale.

Currently, various techniques and methods for determining the quality and safety of food products have been developed. First of all, these techniques and methods are aimed at identifying and detecting any deviations from the norm in the products and preventing substandard products from being sold, as this can lead to negative consequences for the health of the consumer. In this direction, our research is also carried out, pursuing the main goal – the admission to the sale of good-quality food products.

When doing an organoleptic evaluation of carcasses, attention is paid mainly to the degree of exsanguination (good, satisfactory, bad and very bad), the condition of the cut place (if any), pathoanatomical changes in the carcass, organs, and lymph nodes. In the meat of sick animals, a bad or very bad degree of exsanguination is usually noted, which is manifested by the presence of blood in the vessels.

The degree of exsanguination of the carcass is one of the objective indicators that gives information about the condition of the animal before slaughter, the worse the carcass is exsanguinated, the more doubts arise about the health of the slaughtered animal, or there are suspicions that the carcass was obtained from a fallen animal.

Basically, the degree of exsanguination of carcasses of slaughtered animals is determined visually by organoleptic methods of research by external inspection. Often, a method is used to determine the degree of exsanguination of meat with the use of filter paper, which is inserted into a fresh cut of muscle tissue. With a poor degree of exsanguination, a strip of filter paper (1.5 x 10 cm) is soaked above the surface of the meat by 0.3-1 cm.

A microscopic method is used to determine the degree of exsanguination of meat, in which sections of muscle tissue are crushed in a compressorium. With a good and satisfactory exsanguination, there are no traces of blood, and with a bad one, blood spots and capillaries filled with blood are detected (Seregin I.G., Usha B.V., 2008).

A method for determining the degree of exsanguination according to Zagayevsky is known (Senchenko B.S., 2001). To perform it, 25 g of muscle tissue is taken and ground, 0.2 n of hydrochloric acid solution is added in a volume of 5 ml and rubbed until a brick-red color appears. The mixture is squeezed through a gauze cloth, then 0.5 ml of the extract is poured into a test tube of the Sali hemoglobin meter and a 0.2 n solution of hydrochloric acid is added drop by drop to the same color as standard test tubes. The upper division of the test tube shows the percentage of hemoglobin in 0.5 ml of the extract.

A modified Goyal M.M. and Basak A. technique is also used by determining hemoglobin. In this reaction, heme acts as a chemical catalyst, separating hydrogen peroxide into water and releasing oxygen. The resulting oxygen oxidizes o-tolidine with the result that it acquires a green-blue color. The rate of color development is directly proportional to the concentration of hemoglobin (Goyal M.M., Basak A., 2009).

Thus, from the presented literature data, it can be seen that there are many ways to determine the degree of exsanguination of carcasses of slaughtered animals, but almost all of them are of high quality, and some are difficult to implement.

As a result of the experiments, we have developed a method for determining the degree of exsanguination of meat, which allows us to determine the meat obtained from animals that were sick, fallen, or killed in a state of agony. In addition, the method can also be used in the evaluation of Halal products.

The degree of exsanguination of the carcass is one of the objective indicators that gives information about the condition of the animal before slaughter, the worse the carcass is exsanguinated, the more doubts arise about the health of the slaughtered animal. There are several methods for determining the degree of exsanguination of carcasses, but they are all visual and qualitative, we experimentally developed "Quantitative method for determining the degree of exsanguination of carcasses".

The method allows you to identify the adulteration of meat obtained from dead or sick animals, which is a danger to the health of consumers. The technical result is achieved by the fact that the adulteration of meat is determined by the level of the enzyme catalase in the blood, which depends on the state of health of the animal's body before slaughter. In this way, it is possible to determine the meat obtained from fallen animals, animals killed in agony, or sick animals.

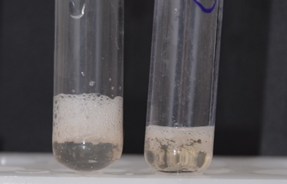

The method is performed using hydrogen peroxide (H2O2). The essence lies in the fact that the hydrogen peroxide added to the meat extract reacts with the enzymes present in the blood and mainly catalase, as a result of which oxygen is released (Sies H., 1991), while a stable column of foam is formed (Figure 1), the amount of which depends on the degree of exsanguination of the animal carcass. At the same time, the worse the degree of exsanguination, the more foam is formed. According to many authors, catalase activity is higher in the red blood cells of sick animals (M. Issi, Y. Gul, S. Yilmaz, 2008; Kassabova T., Staykova M. et al., 1990). Also, under the influence of hydrogen peroxide, the protein fractions of the meat extract (juice) are clarified, in which the optical density is subsequently determined.

The method is carried out as follows:

1. Prepare the meat extract in a ratio of 1: 10.

2. Add 1 ml of filtered extract to the measuring tube.

3. Add 5 drops of 5% hydrogen peroxide solution to the hood and mix intensively.

4. Measure the height of the persistent foam.

5. Measure the optical density of the clarified hood.

Figure 1 – The amount of foam formation during adulteration of meat (left) and meat obtained from a healthy animal (right)

Evaluating the result:

In the meat obtained from sick animals, a persistent column of foam is formed, more than 0.5 cm high. In the meat of healthy animals, foam does not form or slightly covers the surface of the hood (up to 0.5 cm).

The implementation of the method is possible with the use of the developed test set.

In controversial cases, the degree of freshness of meat can be determined by measuring the optical density of the meat extract after the introduction of hydrogen peroxide. Thus, in the extract of cattle meat obtained from healthy animals with a good degree of exsanguination, the optical density is on average 0.455, in meat with a poor degree of exsanguination obtained from a sick animal – 0.516.

The proposed method can be used as one of the objective indicators when assessing the safety of meat by specialists of veterinary laboratories, food safety laboratories, especially in controversial cases when organoleptic studies alone will not be enough.

The innovative patent of the Republic of Kazakhstan No. 31583 entitled "Method for determining the safety of meat" (Certificate No. 12 of 30.09.2016) was obtained for the method.

The data is taken from the monograph: Modern aspects of quality control and food safety. Balji Yu.A., Adilbekov Zh.Sh – Saint-Petersburg: Lan, 2019. - 216 p. https://e.lanbook.com/book/116370